Dakshina Kannada Cooperative Milk Producers' Union Ltd.

(DKMUL)

Expansion, Quality and Rural Welfare:

The Balanced Trade-off

Abhishek Sinha and

Sahana Shenoy

Batch

2005-07, TAPMI.

Please click here to refer Annexure

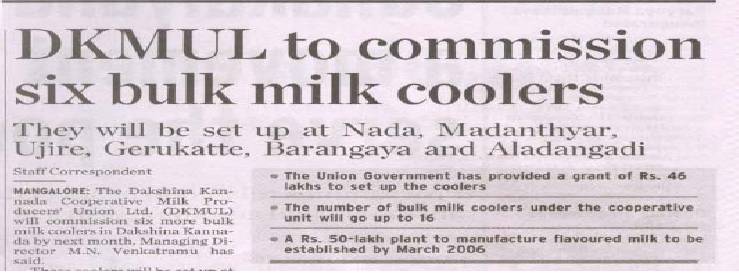

Dakshina Kannada Cooperative Milk Producers' Union Ltd. (DKMUL) is a cooperative society with a difference. Established in 1984*, DKMUL has come a long way from being a small co-operative society to being a big name in the Karnataka State Milk industry today. DKMUL started with a capacity of collection and processing of around 4000* liters of milk and today collects 1.78 lakh liters of milk from 36,000 farmers in 496 milk cooperative societies a day**. This expansion has been brought about in tandem with intensive progress in standards of quality and constant increase in profit margins. Throughout the fast growth of the co-operative, it has been able to strictly achieve its mission of distributing the profits to the rural milk producers and consumers by complete removal of middlemen and encouraging the rural milk producers to produce quality milk and milk products at reasonable rates for consumption by the rural and urban population*. We intend to delve a bit deeper into how the expansion has been brought about both in terms of revenue and capacity defying the inversely related big jumps made by DKMUL in quality standards, expansion and rural welfare.

The co-operative has been growing at around an approximate average rate of 30% with a predicted capacity growth for the Mangalore plant of nearly 50% in the next one year with assistance from National Dairy Development Board (NDDB)**. This growth is being predicted after the decision to upgrade the milk processing plant in Mangalore at an estimated cost of Rs. 4.65 crores. The up gradation is estimated for completion in a year and this plant will then be able to increase it’s milk processing capacity to two lakh liters of milk a day against the existing one lakh liters.**

In spite of the growth and profits, a huge amount of money and efforts is spent on maintaining high standards of quality, which is achieved through extreme cleanliness of premises, machines and materials used, a thorough method of testing which uses the latest technology, benchmarking of quality standards and adoption of the latest

and the highest quality improvement methods in the industry.

Being an industry which

produces consumables which have a direct impact on public health, DKMUL clearly

realizes its responsibility to deliver clean and hygienic milk. The premises

are kept absolutely clean, with not even a drop of spilled milk visible

anywhere, which was very evident on every visit to the different plants of

DKMUL. At an average, the plant is cleaned thoroughly after every collection

cycle*. A special automated machine cleans the milk cans in three stages after

the reception cycle. The three stages include cleaning with i)

Report) All these pipes are cleaned by a completely automated process called Clean In Place (CIP) which cleans in 4 phases: With i) Normal water ii) Hot water iii) Acids iv) Alkalis, which are passed through the paths in which milk flows.

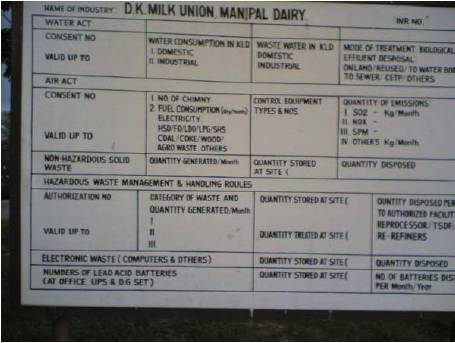

DKMUL is highly environment conscious and has a separate water treatment plant which in the Manipal plant treats the water in 5 different stages. DKMUL also follows thorough quality testing of milk in all the stages. A 100ml. sample is taken from each lot, during collection, labeled and sent to the quality lab for quality testing. The milk is tested for a minimum standard of 3.5% Fat and 8.5% SNF (Solid Not Fat) ratios. At the time of writing this case, the rate of purchase of milk from the producers was Rs.10.25 per kg. A 20 paisa per kg reward is given for every 0.01% increase in the fat ratio above standard and severe penalties are imposed if the fat or SNF ratios fall below the standards*. Apart from this there are separate labs for microbiological testing of milk to ensure Prevention of Food Adulteration Act (PFA) compliance.

DKMUL is growing exponentially, and being a true co-operative DKMUL has maintained its motto of channelising all profits to benefiting its customers and the milk producers, and working for rural welfare. It has invested a lot of money in organizing rural welfare workshops, seminars, sponsoring rural projects and in bringing together banks and other financing bodies to benefit the rural population at large. It has tried to help it’s customers by continuously trying to improve the quality standards, organizing fortnightly surprise visits and checks to the milk societies and giving Clean Milk Production Training to the rural milk producers. It has also balanced rural welfare by adopting high international quality norms like Total Quality Management (TQM), Clean Milk Production (CMP), Total Energy Management (TEM), International Organization for Standardization (ISO), and Hazard Analysis Critical Control Points (HACCP).

Thus DKMUL along with its huge growth in capacity and revenue has also managed an increase in quality standards and maintaining the concern for the welfare of its rural milk producers, with a very balanced and an organized approach.

Please click here to refer Annexure

NOTE:

NOTE:

• This

case is for academic purposes only and using the data or analysis for business

purposes is strictly prohibited.

• This

case is written with the help of visits to the Mangalore and Manipal Plants of

DKMUL and with the information provided by DKMUL officials and that available

on the internet.

• A

special thanks to TAPMI student core group I-2 (Batch 2005-07) for

sharing its

analysis and data.

* As told to the

authors by DKMUL executives on visits to the Mangalore and Manipal Plants

** Source: The

Hindu, Jan 09, 2006